Reference Manual

Chapter 6: Electrical/Interior: Rallye Pac Conversion

The standard Oldsmobile Cutlass instrument panel, with little

more than a speedometer, fuel gauge and a collection of "idiot" lights

leaves much to be desired for anyone with the least bit of interest in what is

happening under the hood. Fortunately, Oldsmobile offered, as an option, an

instrument panel that included a basic set of gauges and this instrument panel can

be swapped into a G-body that was originally equipped with the standard instrument

panel with some minor rework of the original wiring.

Parts required:

- "Rallye Pac" Gauge Cluster Assembly

- Water temp sender (single terminal)

- GP Sorenson p/n tsu64

- or

- the equivalent

- Oil sending unit for cluster with gauges

- GM p/n 14036243

- or

- GP Sorenson p/n ops88

- or

- the equivalent

- Brass extension for oil sender to clear the intake

manifold and cruise control bracket.

- GM p/n 401559

- or

- 1/8" NPT brass 45° elbow and a 2" long

1/8" NPT brass nipple

- or

- the equivalent

- 18awg wire

Tools required:

- 5.5mm socket

- 7mm socket

- 1/4" socket

Time required:

While not difficult, a few things related to this swap may take

some time to work out. Although it may take less time, plan on an afternoon to

complete this conversion.

Overview:

The standard Oldsmobile Cutlass instrument panel is wired

differently than the cluster with gauges. For this reason a swap from the standard

cluster to a Rallye Pac cluster will require the rearrangment of the terminals in

one of the cluster connectors.

| Standard Cluster |

|

|

Connector 1: |

Connector 2: |

|

| 1. |

Service Engine Soon Ind. |

Yel |

1. |

LH Turn Indicator |

Lt. Blu |

| 2. |

(Blank Indicator) |

|

2. |

Ground |

Blk |

| 3. |

(Blank Indicator) |

|

3. |

Illumination |

Gry |

| 4. |

(2nd Coolant Temp Ind.) |

|

4. |

Charge Indicator |

Brn |

| 5. |

(2nd Coolant Temp Ind.) |

|

5. |

Illumination |

Gry |

| 6. |

(Wait Indicator) |

|

6. |

Ground |

Blk |

| 7. |

(2nd Fasten Belts Ind.) |

|

7. |

Fuel Gauge |

Pnk |

| 8. |

(Water in Fuel Ind.) |

|

8. |

RH Turn Indicator |

Dk. Blu |

| 9. |

Not Used |

|

9. |

Fasten Belts Indicator |

Yel |

| 10. |

Not Used |

|

10. |

Brake Indicator |

Tan/Wht |

| 11. |

Not Used |

|

11. |

Coolant Temp Indicator |

Dk. Grn |

| 12. |

Not Used |

|

12. |

Ignition Input |

Pnk/Blk |

| 13. |

Not Used |

|

13. |

Oil/Choke Indicator |

Tan |

| 14. |

(Low Fuel Indicator) |

|

14. |

Hi Beam Indicator |

Lt Grn |

| Gauges Cluster |

|

|

Connector 1: |

Connector 2: |

|

| 1. |

Service Engine Soon Ind. |

Yel |

1. |

Illumination |

Gry |

| 2. |

(Blank Indicator) |

|

2. |

Ground |

Black |

| 3. |

(Blank Indicator) |

|

3. |

Fuel Gauge |

Pnk |

| 4. |

Coolant Temp Indicator |

Dk Grn/Yel |

4. |

Oil Pressure Gauge |

Tan |

| 5. |

Ignition Input |

Pnk/Blk |

5. |

Fasten Belts Indicator |

Yel |

| 6. |

(Wait Indicator) |

|

6. |

Brake Indicator |

Tan/Wht |

| 7. |

(2nd Fasten Belts Ind) |

|

7. |

Coolant Temp Gauge Input |

Dk Grn/Wht |

| 8. |

(Water in Fuel Ind.) |

|

8. |

(Oil/Choke Indicator) |

|

| 9. |

Not Used |

|

9. |

Charge Indicator |

Brn |

| 10. |

Not Used |

|

10. |

Ignition Input |

Pnk/Blk |

| 11. |

Not Used |

|

11. |

Hi Beam Indicator |

Lt Grn |

| 12. |

Not Used |

|

12. |

LH Turn Indicator |

Lt Blu |

| 13. |

Not Used |

|

13. |

RH Turn Indicator |

Dk Blu |

| 14. |

(Low Fuel Indicator) |

|

14. |

Tachometer Input |

Wht |

From the above charts, the first thing you might notice is that

all functions use the same color code for each function wire, for both clusters.

Not quite so obvious at first glance, the standard cluster uses 2 each of the

illumination and ground leads, whereas the gauges cluster uses only one of each.

This means that when doing this swap you'll have an extra

ground and an extra illumination wire. Because for both clusters each connects to

the same location in the wiring harness and all are of the same gauge, which of

each you use for the swap is irrelevant and the extra of each wire will need to

protected from shorting out and stuffed away behind the dash.

The Procedure:

- The first step is to remove

the original cluster.

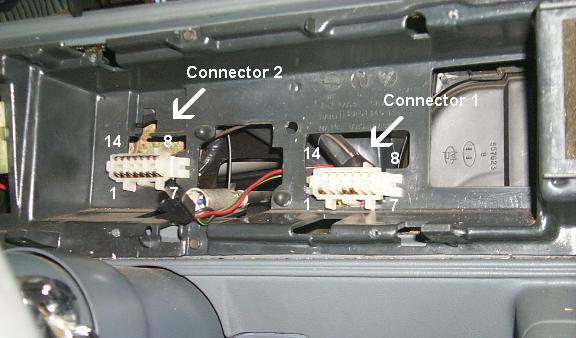

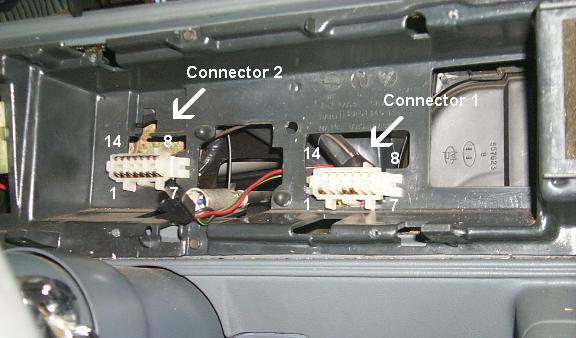

- With the original cluster removed, push the locking tabs on

either side of connector 2 toward the center of the connector and push the

connector in so that it passes through the instrument panel adaptor.

- Connector 2 can then be passed through the larger opening

above it's installed location and pulled away from the i.p. adaptor so that you

can gain access to the terminals.

- Each terminal is secured in the connector shell by a locking

tang. To remove a terminal you must insert a small pick, awl, jewelers

screwdriver or similar tool between the terminal and the connector shell to

depress the tang, releasing the terminal. With the tang depressed, the terminal

will pass through the shell by pulling on the wire. Do not use force!

When the tang has been sufficiently depressed the terminal will pull

out easily with little to no effort.

- While the terminals are removed, inspect each terminal

closely for any corrosion or tarnish. If any corrosion or tarnishing is present,

remove it using an eraser or a cloth soaked in rubbing alcohol. Do not use an

abrasive, each terminal is steel with a thin copper coating, the use of an

abrasive will degrade the copper coating allowing the steel terminal to corrode.

- Rearrange the terminals in Connector 2 by color code using

the chart below:

| Connector 2 |

|

|

Standard Cluster: |

Gauges Cluster: |

|

| 1. |

LH Turn Indicator |

Lt Blue |

1. |

Illumination |

Gray |

| 2. |

Ground |

Black |

2. |

Ground |

Black |

| 3. |

Illumination |

Gray |

3. |

Fuel Gauge |

Pink |

| 4. |

Charge Indicator |

Brown |

4. |

Oil Pressure Gauge |

Tan |

| 5. |

Illumination |

Gray |

5. |

Fasten Belts Indicator |

Yel |

| 6. |

Ground |

Black |

6. |

Brake Indicator |

Tan/Wht |

| 7. |

Fuel Gauge |

Pink |

7. |

Coolant Temp Gauge Input |

Dk Grn/Wht |

| 8. |

RH Turn Indicator |

Dk Blue |

8. |

(Oil/Choke Indicator) |

|

| 9. |

Fasten Belts Ind. |

Yellow |

9. |

Charge Indicator |

Brown |

| 10. |

Brake Indicator |

Tan/Wht |

10. |

Ignition Input |

Pnk/Blk |

| 11. |

Coolant Temp Indicator |

Dk Grn |

11. |

Hi Beam Indicator |

Lt Grn |

| 12. |

Ignition Input |

Pnk/Blk |

12. |

LH Turn Indicator |

Lt Blu |

| 13. |

Oil/Choke Indicator |

Tan |

13. |

RH Turn Indicator |

Dk Blu |

| 14. |

Hi Beam Indicator |

Lt Grn |

14. |

Tachometer Input |

Wht |

- When reinserting the terminals into the connector shell, it

is very important that the tang be bent away from the terminal so that it will

be able to properly secure the terminal in the shell. If this is not done, or

done improperly, it's likely that the terminal will slip out of position in the

connector shell and make poor, or no, contact with the cluster. Resulting in

inaccurate, or non-functional gauges or functions. An easy way to check each

terminal is to push on them as if removing them from the housing, if the tang is

holding the terminal in the housing, the terminal will only move a short

distance in the connector housing.

- Looking at the chart above, you'll notice that the Standard

Cluster uses 2 each of the Illumination and Ground wires, while a Gauges Cluster

uses only one of each. The spare of each of these lead wires should be protected

from shorts (such as with electrical tape) and securely fastened to the wiring

harness behind the cluster to prevent future problems.

- This will leave 2 circuits that will require special

attention:

- The Tachometer

- Method 1 (Recommended)

- Install a wire, with terminal, in Connector 2,

position 14 (White to match factory color, ideally)

- Route this wire through the firewall to the

distributer

- Attach a 1/4" Quick Disconnect terminal to

the wire and plug this QD terminal into the Distributer TACH

terminal

- Method 2 (The cleanest)

Check

your distributer, if there is already a white wire connected to the

TACH terminal, you could use this method.

- Install a wire, with terminal, in Connector 2,

position 14 (White to match the factory color, ideally)

- Remove the two screws from the opposite corners

of the fuse block

- Pry out the tabs at each corner to seperate the

fuse block from the bulkhead connector.

- From under the hood, loosen the 1/4"

captive screw in the center of the bulkhead connector holding the

two halves of the buckhead connector together.

- Pull the bulkhead connector apart

- Obtain a proper terminal for the bulkhead

connector and attach it to the end of this wire

- Insert the terminal into the bulkhead connector

at position A7

- Reassemble the bulkhead connector and the fuse

block

- The Coolant Temperature Sensor

- Method 1 (Recommended)

- Insert the existing Dk Green wire into Connector

2, position 7

- Remove the original Coolant Temperature Sensor

- Install the Sensor listed in the Parts list or

it's equivalent

- Method 2 (Harder)

This method will alleviate the need to change the Coolant Sensor if your

engine has a two terminal Coolant Sensor.

- Remove the two screws from the opposite corners

of the fuse block

- Pry out the tabs at each corner to seperate the

fuse block from the bulkhead connector.

- From under the hood, loosen the 1/4"

captive screw in the center of the bulkhead connector holding the

two halves of the buckhead connector together.

- Pull the bulkhead connector apart

- Remove the terminal at D5 (Dk Green or Dk

Green/Yellow)

- Reinstall this terminal at location C6

- Reassemble the bulkhead connector and the fuse

block

- Method 3 (The most difficult)

Warning: This method will irrevocably alter your wiring harness.

Because the wiring harness is no longer available new from GM, this

method should only be used after very careful consideration, and is not

recommended.

This method will give you a functional coolant temp gauge and a

functional coolant temperature indicator.

- Extend the Dk Green wire at the Cluster

Connector 2, position 11 of the standard cluster to reach Connector

1 and install in position 4 (this maintains the bulb test function

of the coolant temp indicator).

- Modify the Ignition input lead, Pink/Black, to

also connect to Connector 1, position 5, and install.

- Insert a new wire lead, with terminal, into

Connector 2, position 7 (Dk Green/White to match the factory color,

ideally).

- Remove the two screws from the opposite corners

of the fuse block

- Pry out the tabs at each corner to seperate the

fuse block from the bulkhead connector.

- From under the hood, loosen the 1/4"

captive screw in the center of the bulkhead connector holding the

two halves of the buckhead connector together.

- Pull the bulkhead connector apart

- Obtain a proper terminal for the bulkhead

connector and attach it to the end of this wire lead.

- Insert this wire terminal into the bulkhead

connector at position C6

- Reassemble the bulkhead connector and the fuse

block

Installing the Oil Pressure Sender

- Disconnect the lead wire from the Oil Pressure Switch.

- Remove the original Oil Pressure Switch.

- Install the brass extension.

- Install the Oil Pressure Sender.

- Connect the original lead wire to the Oil Pressure Sender.

Optional method to keep the Oil Pressure Switch and

indicator functional:

- Disconnect the lead wire from the Oil Pressure Switch.

- Remove the original Oil Pressure Switch.

- Install a 1/8" brass hex nipple in the block.

- Attach a brass 45° elbow to the nipple.

- Attach a brass Tee to the elbow.

- Install the Oil Pressure Switch in the upper port of the

Tee.

- Install the Oil Pressure Sender in the remaining port of the

Tee.

- Connect the original lead wire to the Oil Pressure Sender.

- Connect a new lead wire to the Oil Pressure Switch and route

the wire to cluster connecter 2 and install in position 8.

oil pressure sender and switch installed

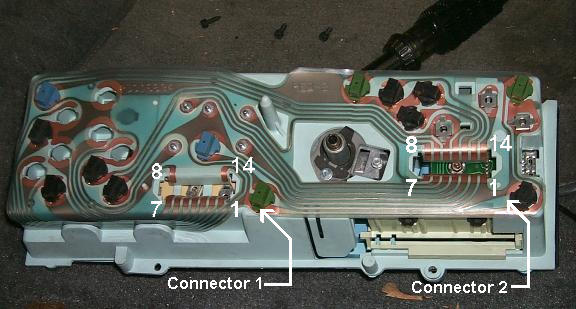

Setting the Tachometer:

The tachometer can be set to indicate RPM for a 6 or 8 cylinder

engine by means of a jumper accessible from the rear of the gauge cluster housing.

- 1. Instrument Cluster Assembly

- 2. Shorting Adapter

-

- Calibrate the tachometer by installing the shorting

adaptor in the hole that matches the number of engine cylinders (6 or 8).

- or

- This would be a good time to consider replacing the jumper with a

soldered connection to eliminate possible

future problems.

Addressing the issue of the Odometer:

- The Legal Situation:

When replacing a speedometer assembly, the law requires the odometer reading of

the replacement unit to be set to register the same mileage as the prior

odometer. If the same mileage cannot be set, the law requires that the

replacement odometer be set to zero and a label be installed on the driver's

door frame to show the previous odometer reading and the date of replacement.

- Now the good news. The odometer assembly used in a standard

cluster is identical to that used in the gauges cluster.

Cleaning the gauge faces:

- Don't do it. The ink used to print the

gauge face is water based. A liquid based cleaning fluid, or even water, will

smear the printing or even completely remove the printing.

|

Table of Contents

|

|

Top of Chapter

|

|

|

Copyright © 1998-2024 by The Members of The Oldsmobile Mailing List. All

Rights Reserved. This web site is not affiliated with General Motors or

Oldsmobile. General Motors and Oldsmobile are trademarks of their respective

companies. The owners and members of this site are not responsible for errors

or inaccuracies.

|